Description

A strong, stain-resistant fiber often used for wallpaper

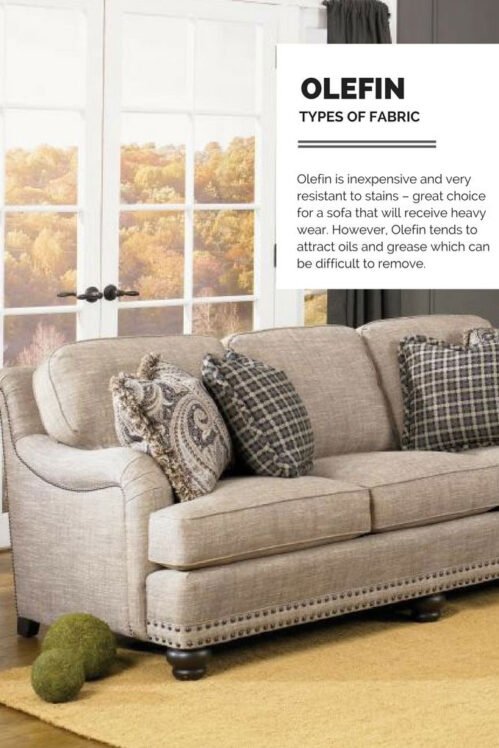

Olefin synthetic fibers are made from polyolefin a term for colorless plastics that feel waxy and oily. The two most important strands are called polyethylene and polypropylene, with polypropylene being more commonly used in the textile industry.

Background

Story

Olefin fibers were first produced in Italy during 1957 by Nobel Prize winners Giulio Natta and Karl Ziegler, to increase the number of textile applications. The United States also started producing olefin in 1960.

Manufacturing

Polypropylene is made from the gas propylene. Propylene is a colorless gas with faint petroleum-like odor. It is a co-product of ethylene production through the steam cracking of hydrocarbons or oil production. I know what you’re thinking… “How can olefin be more sustainable than cotton or silk while being involved with gas and oil production?”

Expertises

Characteristic

- Polyethylene (PE) i t; genera”‘/ lighter

- Polyethylene (PE) i3 rnore stable in ternperature

- Durable

- Buoyant, rnaking it ideal for highperformance apparel

- Low melting temperature, especially polyethylene

- Pill resistant

- Moisture wicking and fast drying

- Stain resistant

- Cannot be dyed

- Lowest static among synthetic fiber

- Non-biodegradable

Is Polypopylene Fabric Safe?

Olefin is inherently safe, but how we treat the olefin is the true measure of health and environmental consciousness.

Chemicals like Polyfluorinated Compounds (PFC’s) are sprayed on furniture, rugs, and apparel to repel water and stains. Anti-microbials and fire retardants are also used but have been found by the Green Science Policy Institute to have health effects. Revolution Performance Fabrics only uses Olefin and the weave design to repel stains. Olefin is chemically stain resistant so there is zero need for water repelling chemicals and antimicrobials that can affect your health. Below are some of the benefits of Revolution Performance Fabrics that are 100% made of olefin.

It’s the Eco-Friendly Choice

One of the biggest benefits of olefin is how eco-friendly it is. Compared to cotton, which is grown, or wool, which is sheered from sheep, the chemical process used to create olefin may sound like the furthest thing from eco-friendly.

But the reality is that the production process involves very little by-product. This means that the ingredients used to create the fabric are completely used. Nothing needs to be thrown away, recycled, or processed.

Incredible Strength

The thick weave and strength of the chemical fibres used to make olefin allow it to be incredibly durable fabric.

Compared to other, weaker natural fabrics or those with a loose weave, olefin can be used to create products that need to be tough. This includes things like outdoor rugs, automotive interior fabrics, and even wall coverings.

The strength of olefin fabric also means that the products it is used to make can hold up to years of use. This makes it a great choice for products like outdoor bean bag chairs or patio cushions, especially in hotel environments where they see constant, heavy use.

Social

12k followers

30k likes

Youtube

22k subscribers

8k followers

Have a project in mind?

If you have a great idea, reach out to me. Whether it is a small or big project, I will listen first and get back to you with a plan.