Description

One of the world’s most widely used fibers, often used for fast fashion.

A synthetic fiber derived from petroleum, polyester is generally available in two types: polyethylene terephthalate (PET) and Poly-I, 4-cyclohexylene terephthalate (PCDT). PET, a stronger type of polyester, is more popular for clothing and is commonly blended with natural fibers. PCDT is more

often used in furnishings due to its elastic and resilient properties.

Background

Story

Terylene, the first polyester fiber, was created in Great Britain between 1931 and 1941. In 1956, the production rights were bought by an American company, DuPont, and renamed Dacron for the United States market. Praised for having zero wrinkles (even after washing), one of the fabric’s earliest uses was for suiting.

Manufacturing

Polyester is the most commonly used synthetic fiber. DuPont introduced its Dacron brand of polyester in 1951, but the material itself was patented earlier in 1941.

It’s made by reacting dicarboxylic acid with dihydric alcohol. This base material can be used to make many things, from soda bottles to boats, as well as clothing fibers. Like nylon, polyester is melt-spun – this process allows the fibers to be made in different shapes and sizes for specific applications. Chemists can now alter the size and shape of polyester fibers to look and feel more like natural fibers. Ultra-thin microfibers can give polyester a smoother, softer feel than the polyester of twenty years ago.

Expertises

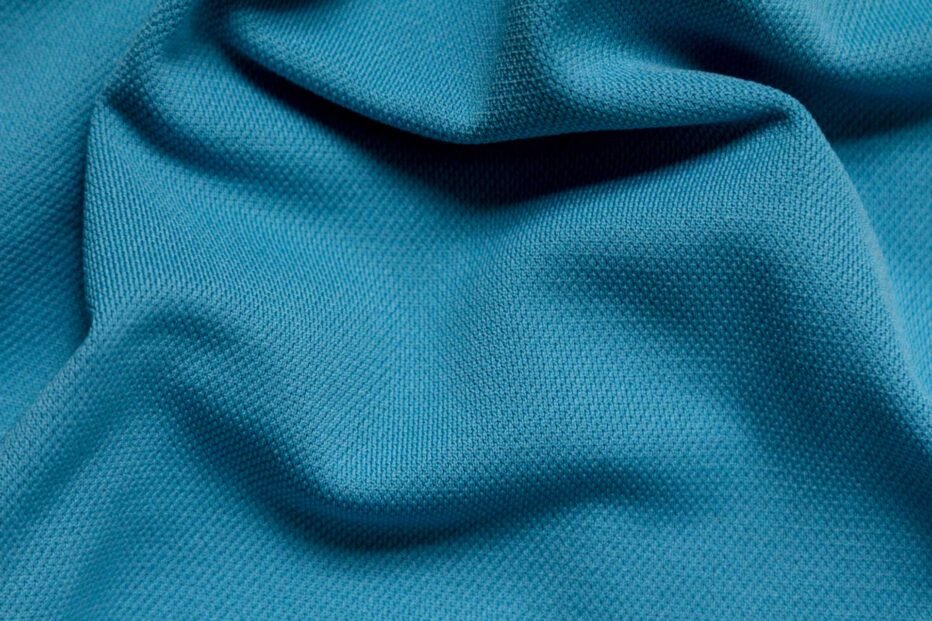

Characteristic

• Soft and drapes easily Holds garment shapes well

• Highly durable

• Retains pleats set by heat

• Pill resistant in filament form

• Fast drying

• Mildew and soil resistant

• Lower price-point than most fabrics

• Takes dye well, requires high-temperature dye

Polymerization

Condensation polymerization occurs when the acid and alcohol are reacted in a vacuum at high temperatures. The polymerized material is extruded in the form of a ribbon onto a casting trough or cooling wheel. After the ribbon hardens, it is cut into chips.

Derived from non-renewable petrochemicals

Polyester is a synthetic fiber, but its raw materials still come from nature. Most polyester is made out of petroleum, a natural non-renewable resource. Right now, we’re using up petroleum much faster than it can be produced in nature. Some predictions indicate we could reach peak oil (maximum extraction) by 2030.

Producing plastic-based fibers for textiles uses an estimated 342 million barrels of oil every year, according to A New Textiles Economy Report 2017.

Dye process is generally better than for natural fibers.

According to the NRDC, polyester requires high temperature dying processes, but the process is shorter and requires less chemical use, making the overall impact lower than for fibers like cotton. Suggestions: Choose more sustainable dyes and finishes.

Social

12k followers

30k likes

Youtube

22k subscribers

8k followers

Have a project in mind?

If you have a great idea, reach out to me. Whether it is a small or big project, I will listen first and get back to you with a plan.